Intro

Environmental Risks & Impacts

Battery storage systems allow for fluctuating renewable energy sources to be as stable as conventional systems. They also provide means to decouple the generation of electricity from its use (i.e. provide electricity to the grid during peak demand). Batteries may be a good system for load shaving and reduce demand charges, but how to select the best technology for your application?

Different battery storage technologies are used all over the world for grid stabilisation, load leveling and to provide uninterrupted power supply.

The main environmental risks or impacts associated with battery storage facility are outlined below and discussed in detail in this section:

- Leaking of battery and/or spillage of electrolytes.

- Risk of fire, explosion or release of toxic gas.

- Visual impact.

- Replacement of materials and waste generation.

Details

Redox Flow Battery

The Redox Flow Battery tanks hold their charge virtually indefinitely because no phase change or plating occurs in a Redox Flow Battery (such as an ICB flow battery), and thus the electrolyte is a capital cost and permanent asset. The flow battery and/or electrolytes do not need to be replaced, unlike all other battery technologies.

When decommissioning a vanadium redox system, the solid ion exchange cell membranes may be highly acidic or alkaline and therefore toxic. They should be disposed of in the same manner as any corrosive material. If possible, the liquid electrolyte is recycled.

Risk Assessment

Compared to the other types of battery, flow type battery has little environmental concerns as it requires stringent operating condition which separates them from the general environment at the first place. And it is fully recycle-capable due to its solution alike property.

Vanadium redox batteries have two main advantages over other flow battery chemistries.

First, the positive and negative electrolytes are the same when the battery is in a discharged state. This has several implications for cost, manufacture, and efficiency. Costs to ship, store, and manage electrolyte are low and the electrolytes will not contaminate each other should they be mixed (the battery will only self-discharge).

Second, the sulfuric-based electrolyte does not release poisonous or corrosive vapours like other flow batteries using halide-based electrolyte

VRBs do not require emissions or fuel handling permits as part of siting costs. The ion exchange membrane, however, is toxic. During decommissioning, the vanadium electrolyte is recycled and does not face the same environmental and restrictions as lead-acid and cadmium disposal.

Lithium Ion Battery

They are able to store more power in a more compact space, as well as promising a longer lifespan and higher efficiency. They are capable of completing 7,000 full cycles of charge and discharge cycles before they can experience loss

Disadvantages: A notorious disadvantage of Li-ion battery will be the cost. They are more expensive than the lead-acid batteries. Another big issue is safety—providing protection needs to be well considered when using Li-ion battery.

Safety is a serious issue in lithium ion battery technology. Most of the metal oxide electrodes are thermally unstable and can decompose at elevated temperatures, releasing oxygen which can lead to a thermal runaway. To minimize this risk, lithium ion batteries are equipped with a monitoring unit to avoid over-charging and over-discharging. Usually a voltage balance circuit is also installed to monitor the voltage level of each individual cell and prevent voltage deviations among them. Lithium ion battery technology is still developing, and there is considerable potential for further progress. Research is focused on the development of cathode materials.

The normal operating temperature regime of NaS cells during discharge/charge cycles is in the range of 300oC to 350oC. The NaS batteries use hazardous materials including metallic sodium, which is combustible if exposed to water. Therefore, construction of NaS batteries includes airtight, double-walled stainless-steel enclosures that contain the series-parallel arrays of NaS cells. Each cell is hermetically sealed and surrounded with sand both to anchor the cells and to mitigate fire.

The sodium, sulphur, beta- alumina ceramic electrolyte, and sulphur polysulfide components of the battery are disposed of by routine industrial processes or recycled at the end of the NaS battery life.

Other safety features include fused electrical isolation and a battery management system that monitors cell block voltages and temperature.

Lead Acid Battery

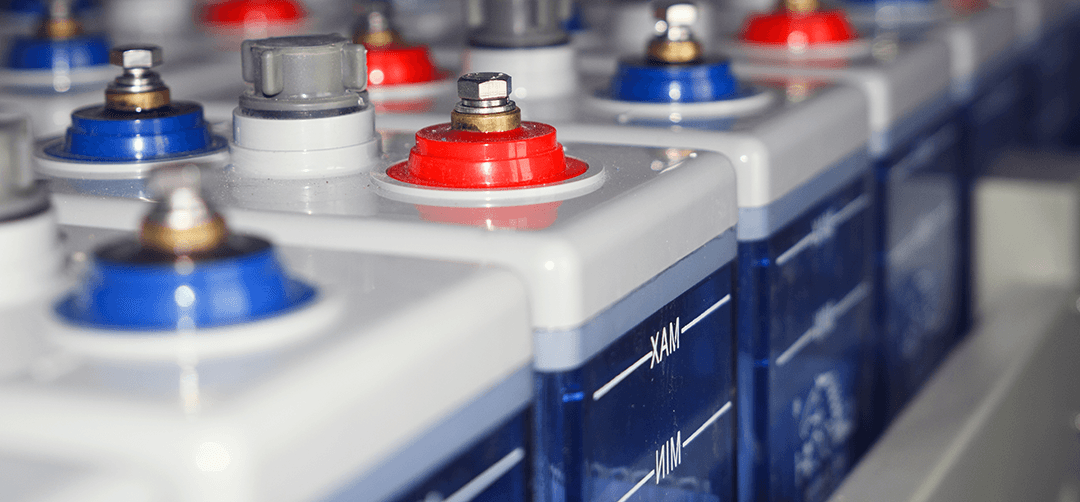

Lead Acid Batteries are reliable and cheap. Multiple deep-cycle lead-acid batteries can provide a steady current over a long time period. They are connected together to form a battery bank. They can provide up to 1MW power to backup wind farm power generation.

Disadvantages: One disadvantage of lead acid battery is that during discharge, the acid will react with electrodes to form lead sulphate, and when the chemical process is reversed during recharging, some of the lead sulphate does not re-dissolve. This will weaken the battery. The greater the depth of discharge, the more the battery is weakened.

Lead-acid batteries contain sulphuric acid and large amounts of lead. They are highly corrosive and can produce a range of adverse health effects particularly in children.

The harmful substances can permeate into the soil, ground water and surface water through landfills.

The importance of recycling the used lead acid battery is big, and the process is among the most complicated.

For solid state batteries, the replacement would mean the removal of a container and replacement with a new battery. The operational lifetime of the solid state battery is 3-12 years for a lead-acid battery

Disposal of lead-acid batteries is an important part of the life cycle. The environmental and safety hazards associated with lead require a number of regulations concerning the handling and disposal of lead-acid batteries. Lead-acid batteries are among the most recycled products in the world. Old batteries are accepted by lead-acid manufacturers for recycling. Batteries are separated into their component parts. The lead plates and grids are smelted to purify the lead for use in new batteries. Acid electrolyte is neutralized, scrubbed to remove dissolved lead, and released into the environment. Other component parts such as plastic and metal casings are also recycled. Any materials that are replaced should be appropriately handled and sent to a registered hazardous landfill site.